Solving a Problem, Enhancing a Space…Sodexo 2020

Environmental Design

Product Design

Background

Our client, Sodexo, was preparing to welcome over 500 employees back to their Buffalo, NY offices after months of having 98% of the workforce working remotely. While they had already implemented effective disinfecting, distancing, and tracking protocols, the challenge remained: how to make 120,000 square feet of open office space feel safe and comfortable.

In addition, New York State regulations required enhanced COVID-19 safety measures once occupancy exceeded 50%, making physical barriers between workstations a necessity.

Several vendors proposed prototypes, but none considered long-term aesthetics or material compatibility with the building’s existing design. Since we had been involved in the building’s original interior design, wayfinding, and experiential graphics, we knew how important it was to create a solution that felt cohesive and intentional—something that would blend seamlessly with the space employees and visitors had come to know.

Challenges

The most commonly used material for safety barriers—plexiglass—was in short supply, and standard retail fixtures were increasingly difficult to source.

Our solution needed to meet a number of key criteria:

- Provide a safe barrier between employees

- Allow natural light to pass through, while offering privacy

- Withstand frequent cleaning

- Be durable and built for long-term use

- Allow for easy removal, if needed

- Be made from readily available materials

- Install quickly

- Complement the existing interior design

These limitations became an opportunity for creative problem-solving. We selected twin-wall polycarbonate, a material typically used in greenhouse construction, for its rigidity, light diffusion, semi-privacy, sleek appearance, and availability.

Since no off-the-shelf hardware met our needs, we custom-designed every component and had it fabricated in aluminum in collaboration with a local vendor.

Because COVID-19 restrictions were still in place during the installation phase, professional installers were difficult to find. To keep things moving and ensure quality, the SVML team installed the entire system ourselves, maintaining accuracy and full control over the final result.

Success

The workstation extensions blended beautifully with the building’s design. The custom aluminum hardware added a subtle, sophisticated design detail, while the panels provided the privacy and protection employees needed.

The client was very happy with the outcome, and the vast majority of employees appreciated the added sense of comfort and safety as they returned to the workplace.

Even better, the system was designed with flexibility in mind—so post-pandemic, the client can easily remove or reconfigure the panels as their office needs evolve.

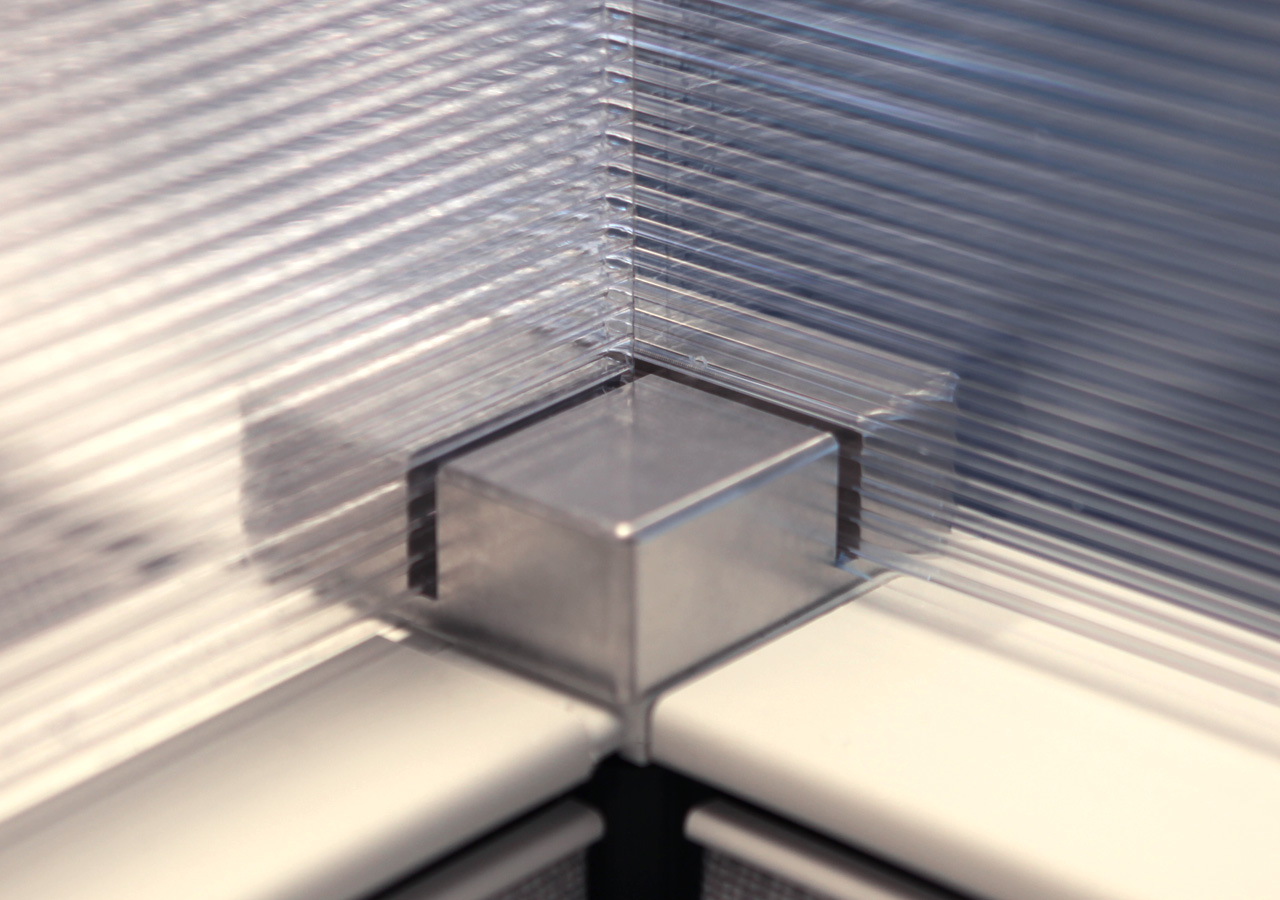

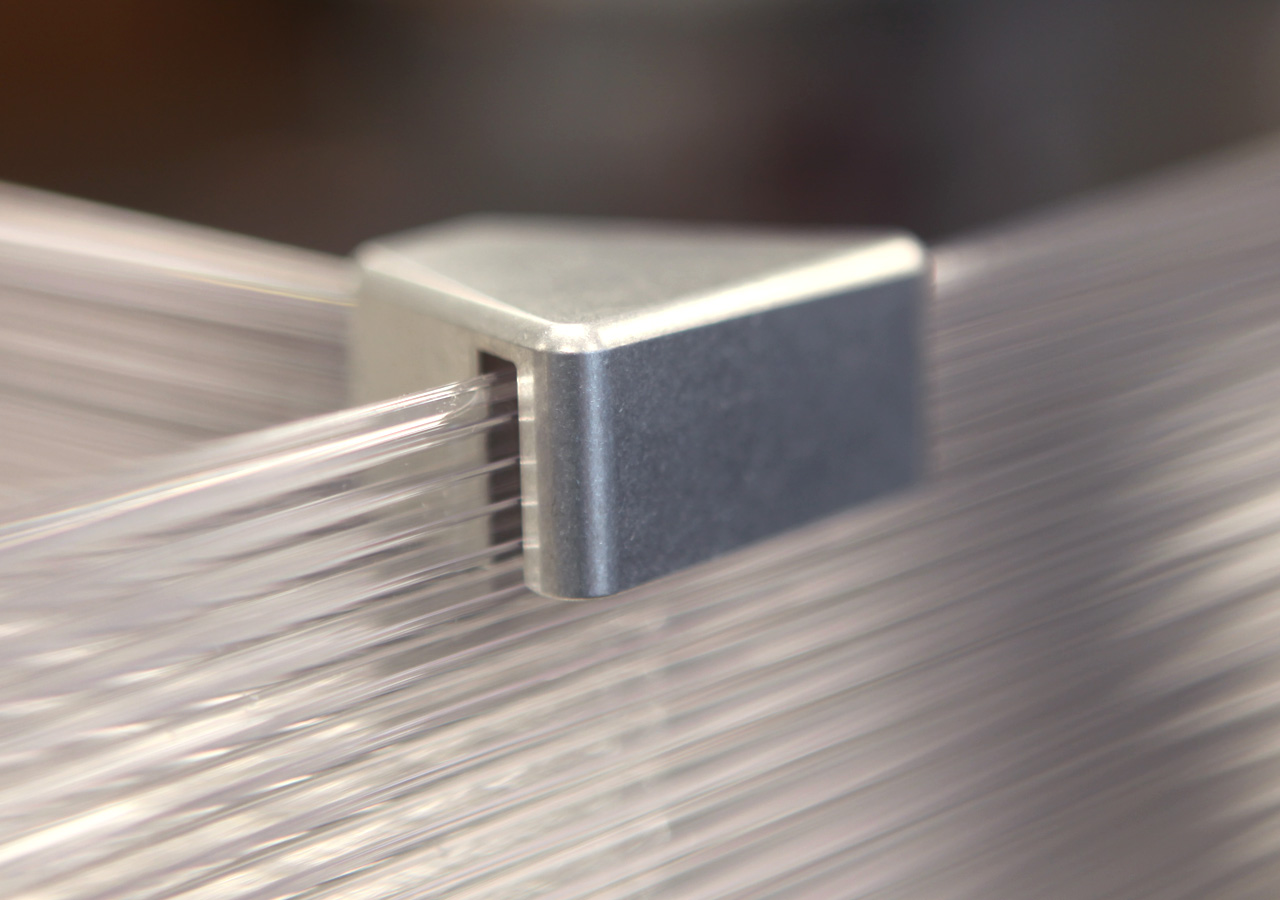

Custom designed hardware to fit the cubicle front panel and securely hold the twin-wall plexiglass protective wall.

Overhead view of workstation extensions in place. All aluminum hardware was custom designed and manufactured.

Detail of custom designed aluminum hardware joining three panels. Hardware to join multiple panels was also created – seven pieces in total.

A Few Prototype Details